|

|

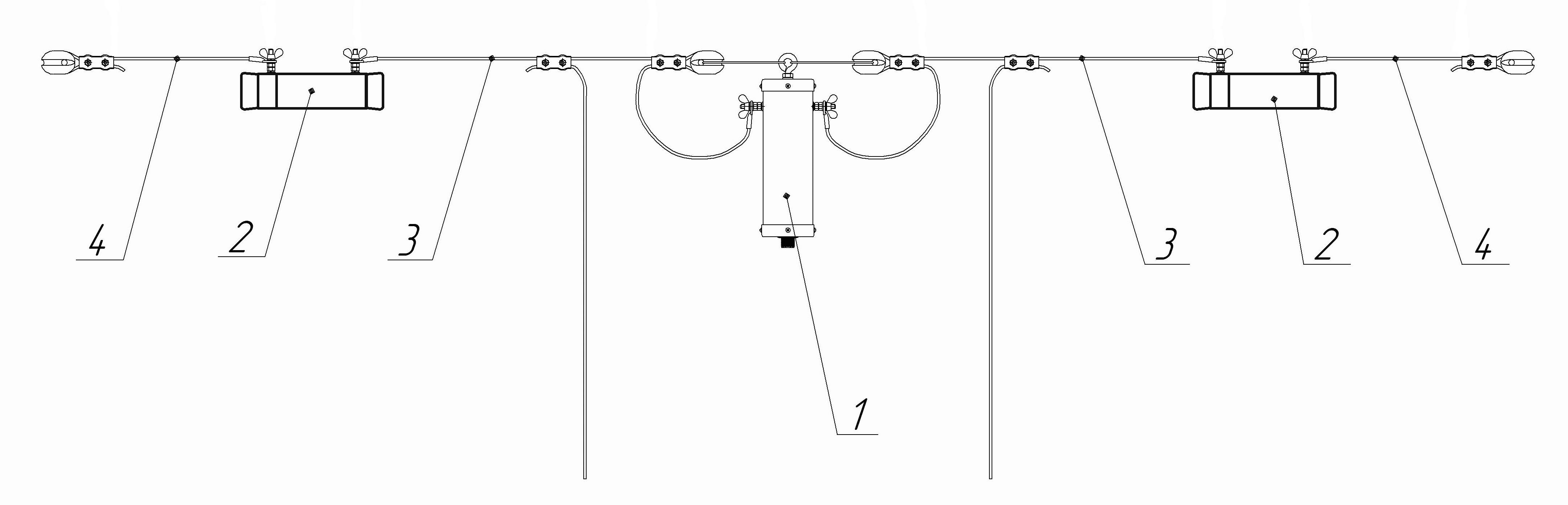

| | Electrical specifications

| Model |

W3DZZ+5.1000

|

| Frequency bandwidth

|

| 80 m VSWR no more 2 |

3.5-3.8 MHz

|

| 40 m VSWR no more 2 |

7.0-7.2 MHz

|

| 20 m VSWR no more 2 |

14.0-14.35 MHz

|

| 15 m VSWR no more 1,5 |

21,0-21,32 MHz

|

| 10 m VSWR no more 2 |

28-29,5 MHz

|

| Impedance, Ohm |

50

|

| Connector |

SO-239

|

| Max. power input*, W |

1000 (SSB, CW)

|

| Length, m |

36

|

| Weight, kg |

2,1

|

| Polarization |

horizontal

|

| Material of radiator |

steel brass wire, PVC insulated

|

| * * The antenna power capacity is defined by the duration of transmission, type of transmission, its frequency, SWR and the ambient temperature.

|

|

|

| |

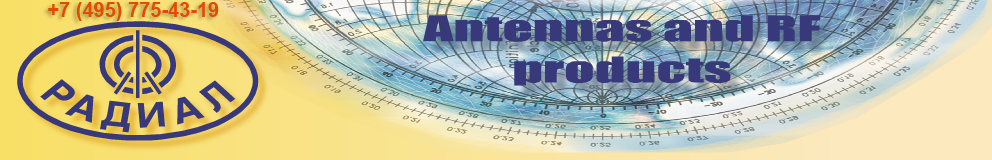

The attempts to introduce the w3dzz+3 tri-band dipole into the European market led to an interesting acquaintance with a new design of an old antenna, with additional 21 and 28 MHz bands. I was told by a well-known Finnish radio amateur Jukka Heikinheimo OH2BR about this design, who, in turn, got to know about the modification from his friend OH2EC.

The new antenna is shown in the figure below. Its differences from the predecessor are as follows:

- The antenna is fed through a 75 О© 1/4-wavelength transformer that improves matching at 14 MHz without considerable SWR deterioration on other bands.

- Two hanging whiskers have finally made the 21 MHz band possible with excellent SWR values.

- Tuning of LC-elements in the antenna traps is optimized for successful resonance trade-off in 80 m and 20 m bands.

The main W3DZZ+5.1000 distinction is introduction of new traps with enhanced dielectric strength in 40 m band. Now the antenna is able to withstand up to 1 kW in this band as well.

Unlike the previous version of W3DZZ+5, traps of this model were modified. Unfortunately, capacitors made from cable cannot survive high voltages at resonance frequency. After several failures to feed 1 kW we had to abandon this idea. New trap capacitors include 5 mm thick dielectric that allows them to survive the specified power reliably. The coil is enclosed in a plastic case. Screws and winged nuts are made of stainless steel. All connections are soldered. To avoid moisture and condensation, the traps are equipped with vent holes. In the process of manufacturing, the traps undergo individual frequency checks and rejection level checks in a test lab.

W3DZZ+5.1000 schem

W3DZZ+5.1000 SWR

|

|

The information provided on this page is not an official offer.

To verify actual parameters contact the sales department before ordering.

|

|